The LAB for Sorption Desalination, Cooling and Green Hydrogen

Mission

We are an innovation Laboratory. We work with the public and private sector to accelerate innovation in their products and services.

We are market developer of niche, innovative technologies in the field of environmental protection and energy efficiency engineering with more than 20 years' experience. Our ambition is to transfer our comprehensive experience on all technical, commercial and scientific aspects to assure sustainable development and achieve cleaner and safer world by a promotion of an advanced generation technologies focused on reduction of primary energy consumption, CO2 & pollution emissions, water production and sewage treatment always by environmentally friendly projects.

Objectives

- To develop cutting-edge research in water desalination and energy production, with a specific focus on applications that lead to CO2 emission reductions.

- To collaborate with industry stakeholders in piloting and testing new methods of water desalination and hydrogen production.

- To train researchers, professionals, and students in advanced water treatment technologies, thereby enhancing the skill set within the Kingdom of Saudi Arabia.

- To attract top-tier researchers from around the world to contribute to the lab’s projects, thereby elevating the institution's research profile.

- To serve as a hub for industrial partnerships, offering a testing and demonstration platform to industry partners interested in adopting water treatment and hydrogen production technologies.

- To conduct research on electrolyzer and water quality, hydrogen storage and fuel cells.

- To ensure that the developed facilities complies with all safety and environmental regulations, incorporating sustainable practices into its design and operation.

- To regularly assess the lab’s performance against predefined metrics, ensuring that the facility remains at the forefront of technological advances.

- To develop a long-term sustainability plan that involves various funding streams, including grants, industry collaborations, and other revenue-generating activities.

Project Areas

1.Zero Liquid Discharge Desalination (ZLDD)

Designed, Manufactured and Tested

The ZLD approach is crucial for water and wastewater treatment. It is a significant technology that will be adopted by a vast industries around the world. However, ZLD technology can be very energy consuming, therefore research on reducing energy consumption and improving process efficiency is now very important.

Each type of the desalination system, which treat the brackish water, sea water, boiler blow down water, cooling tower blown down water or industrial process wastewater produces the desalinated water and the concentrated brine. In many cases, the concentrated brine cannot be discharged directly to the outfall or the other reject point, because proper treatment has to be provided to prevent negative consequences for the environment. In that case, it is possible to use ZLD technology to achieve a Zero Liquid Discharge (ZLD) effect, which converts the concentrated brine into distillate and solid salt.

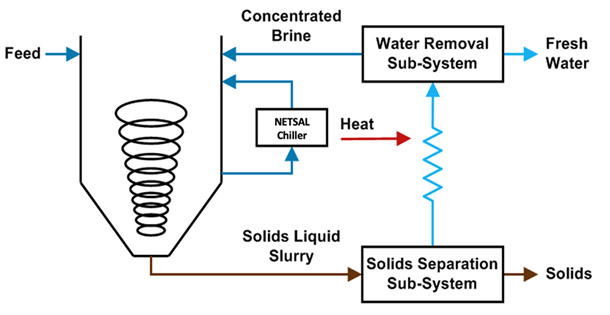

In the Multi-Hybrid ZLD Crystallization System, evaporation is not the main process for achieving ZLD. Elimination of complex and expensive thermal evaporation process provides a cost-effective all-in-one solution, producing distilled water and low water content salt crystals. An additional effect is the production of valuable material in the form of the pure salt crystals. NO BOILING NEEDED MEANS LESS ENERGY CONSUMPTION AND LOWER COSTS

Multi-Hybrid Zero-Liquid-Discharge Crystallization System process diagram.

Laboratory Equipment

- ZLD Crystallization Unit

- NETSAL Chiller

- Water Removal System

- Solid Separation System

- Micro-Nano-Bubbles Generation (MNB®) System

- Oxygen Generation System

- Electrical and control systems

- Probes, measuring and sampling systems

- Frame housing of equipment

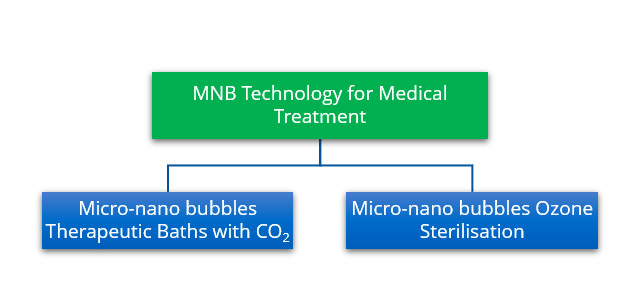

2. Micro Nano Bubbles in Health

Designed and Tested

The use of micro-nano bubbles in the medical industry offers great potential for the treatment of skin diseases. Using the Micro-Nano-Bubble Laboratory Mobile Unit (MNB-MEDAP), it will be possible to carry out research to determine the effects of micro-nano bubbles of different sizes and different gases on improvements in the treatment of skin diseases.

Nowadays, ultrasounds are playing a crucial role in visualizing biological/pathological changes in lives as a reliable imaging technique and a powerful therapeutic tool. Latest ultrasound-based treatment modalities in association with functional micro-nano-bubbles have been highlighted as their great potentials for disease precision therapy. It is believed that these state-of-the-art micro-nano-bubbles will become a booster for ultrasound medicine and visualizable guidance to serve future human healthcare in a more comprehensive and practical manner.

Mobile Micro-nano bubble laboratory system

MNBs combined with US for tumor therapy is still in its infancy, they have tremendous appeal. Their unique structure, multifunctional characteristics, high degree of curative effect and the widespread variety of diseases give MNBs broad development prospect. It should be noted that some challenges and vital issues will need to be discussed and dealt with when they are involved in biomedical applications and future clinical transformations. The most significant areas are indicated below.

Ultrasound irradiation combined with MNBs can treat cancer by improving cancer cell membrane permeability and implosion of the MNBs to deliver drugs or genes directly to tumor cells MNBs ozone sterilization can be used as a better alternative to traditional sterilization techniques as it is faster, degrades more substances (even ozone or antibiotic resistant), requires less ozonated water, and eliminates the need for additional chemicals like detergents MNBs combined with CO2 in therapeutic baths can improve local tissue microcirculation and increases local oxygen supply via the Bohr effect, can cleanse and exfoliate skin, and provides proper skin moisturization (even up to the smallest pores) MNBs can treat diabetic feet and chronic wounds by increasing blood flow and oxygen delivery, eliminating pathogens, and improving local microcirculation MNBs can treat a variety of skin diseases such as psoriasis, atopic dermatitis, and allergies

Laboratory Equipment

- Micro-Nano-Bubbles (MNB) Generation System

- O3 Generation System

- MNBO3 Mobile Skid with Tanks

- Instrumentation, Control & Automation System

- Interconnection Hydraulic & Electrical Installation

- Frame housing of equipment

3. Sludge Reduction & Valorization

Prepared and Tested

The hydrothermal conversion process transforms the waste into a solid carbon material, the hydrochar, which can be used:

- as a biofuel for the production of energy.

- as soil improver;

- as Advanced Carbon Material, in particular as an adsorbent of pollutants in water and gas.

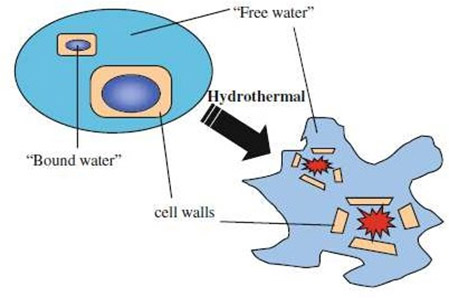

What is Hydrothermal Conversion (HTC)?

- HTC is a process that destroys the colloidal structure of the sludge permitting to the «Bound water» to become «Free water»

- In this way, HTC technology permits to easily dewater the sludge!

- As a consequence the volume of sludge going to landfill will be much lower respect the current situation

Technology Benefits

- REDUCING THE DRY MATTERS (TSS, solids) IN THE SLUDGE

- IMPROVING THE DEWATERABILITY (better solid management)

- IMPROVING THE HYDROPHOBICITY (less water to evaporate)

HTC Lab – HTC Pilot Plant (5 liters Batch Reactor)

- Replication of the HTC Process Conditions

- Possible to use with all types of Sludge both for HTC and HTL

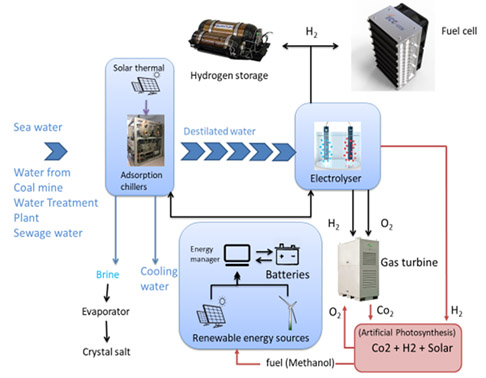

4. Green Hydrogen and Power

Designed, Manufactured and Tested

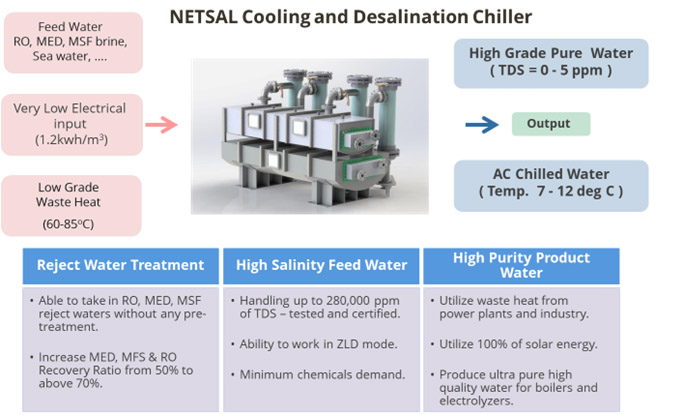

The technology of adsorption desalination of seawater and the production of high-purity distillate for hydrogen production will be developed in such a way that it can be scaled up at the implementation stage and obtaining a distillate production capacity of at least 40 kg / day in production hydrogen at least 1000 cm3 / min green hydrogen.

Objectives

- To develop cutting-edge research in water desalination and energy production, with a specific focus on applications that lead to CO2 emission reductions.

- The primary aim of this application is to reactivate of existing NETSAL Alfaisal Lab for Sorption Cooling and Desalination technology and establishment and operation of a state-of-the-art research lab and center focusing highly innovative seawater desalination technologies and its integration with hydrogen production.

- The technology of adsorption desalination of seawater and the production of high-purity distillate for hydrogen production will be developed in such a way that it can be scaled up at the implementation stage and obtaining a distillate production capacity of at least 40 kg / day in production hydrogen at least 1000 cm3 / min green hydrogen.

- The developed technology is a response to the growing demand for desalinated water and green hydrogen, resulting from the hydrogen and pro-ecological strategies adopted and implemented in the world. For the production of hydrogen, it is necessary to prepare pure process water used in electrolyzers and existing owned by Alfaisal adsorption desalination chiller NETSAL using fluidized adsorption beds producing distillate with lowest possible energy consumption will be a revolutionary solution on the global scale.

- The hydrogen produced can be used to produce electricity in fuel cells or burned in gas engines or gas turbines and can also be used to power hydrogen cars.

Alfaisal Lab has been already equipped with adsorption desalination chiller using fluidized adsorption beds produces in the most effective by energy and cost a very high purity distillate which will be used to produce hydrogen in the electrolyzer.

Benefits| Project Performance and Economical Target

To reduce the cost of green hydrogen production from the current level of 4 - 10 EUR per kg H2 towards 2 euro per kg H2 in 2050. To develop offshore hydrogen production by means of water electrolysis installations. To decrease transport costs and avoid large investments in electrical grids, since transporting gases is less expensive than transporting electricity additionally already existing gas infrastructure can be used. The electrolysis process requires ultrapure water, which is an expensive feedstock in the KSA.

Lab Services

The Lab provides a full suite of innovation services

Lab Services

Our multidisciplinary labs are offered to outside users to either utilize under our supervision, used for training programs or accessed with our technical teams conducting all activities under your direction

Research & Consultation

Access our subject knowledge expertise through one-to-one consultations or funded research work

End-to-end innovation solutions

We work closely with you to identify your innovation related challenges to develop tailored solutions through focused R&D work across multidisciplinary teams.

Spin-off incubator

License our IP for your own requirements or take an equity stake in some of our promising research that is spun-out into a stand alone company.

Contact Person

Dr. Yousef M. Alyousef Mechanical Department College of Engineering Tel: 011-2157803 Email: yalyousef@alfaisal.edu